This project was completed to fulfil the coursework requirement of the second-year Design and Manufacture module which I took at university. The main goals for this project were to develop our teamwork skills as well as our Design for Manufacturability skills to ensure that our innovative ideas could be fabricated and assembled in the workshop.

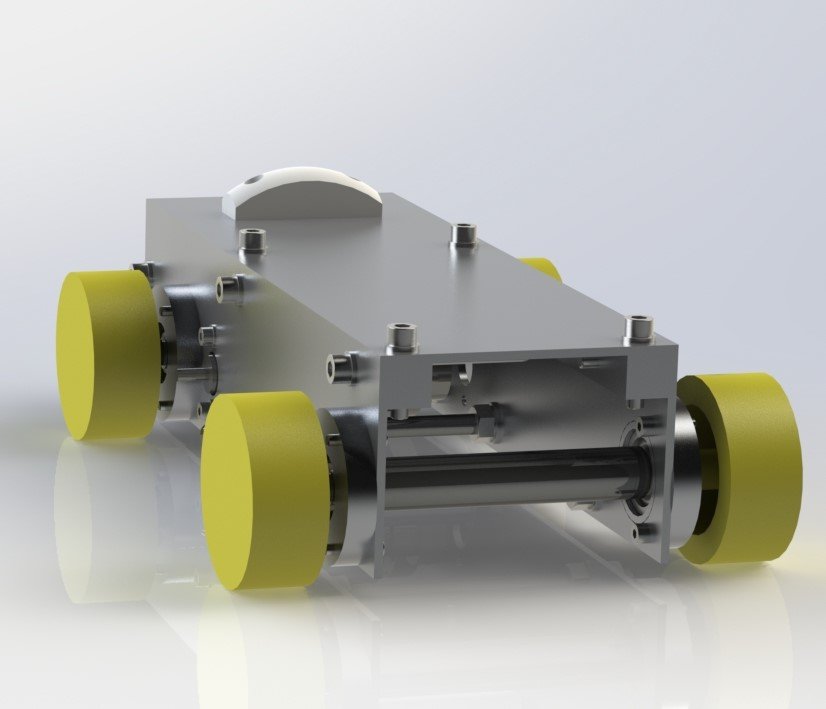

Electric Toy Car

My team and I were very successful in completing all the tasks within the time planned at the beginning of the project despite being faced with difficulties and delays when ordering components from external suppliers. I think this was a great learning experience about the type of complications that can often arise in a real-world project. We also achieved a 3rd place finish in a competition that was held at the end of the project where all 32 teams could test their designs against each other.

Below I have attached some pictures of our design as well as the finished car. I have also quoted the Executive Summary from our project report after the pictures which provides an idea of the different design decisions that were made. The complete report can also be found at the bottom of the page.

Executive Summary

"The group was tasked with designing, manufacturing and testing all the parts required for a small motorized car, including the drive transmission and the chassis. The car was required to participate in both a drag race and torque test. The width of the car was restricted to 200 mm and the team made the decision of aiming for a target weight of around 2 kilograms, without sacrificing traction, with an operating lifetime of a minimum of 100 hours. Other aspects such as build quality, safety, aesthetics and design for manufacturability were also given careful consideration.

"A gear ratio of 2.24:1 was chosen as the best compromise given the parts available from the supplier so that the motor could transmit enough power to the wheels to optimize the performance of the car in both the drag race and torque test. The car did not require a differential or a suspension as the car would only go in a straight line and on a smooth surface. There were many stages the design of the car went through to find the ideal solution that would fit the project description. The final design of the car, shown in the pictures below, included a rear-wheel drive layout with a one step-down drive transmission from the motor, and both the front and rear shaft were rotating shafts.

"Sufficient calculations were conducted to ensure all safety factors were considered for the bearings, shafts and chassis. The final chassis was chosen to ensure the entire drive transmission was within the chassis and was not exposed, for the safe operation of the car."