Uni-Wheel

The design of the mechanical transmission for a self-balancing vehicle

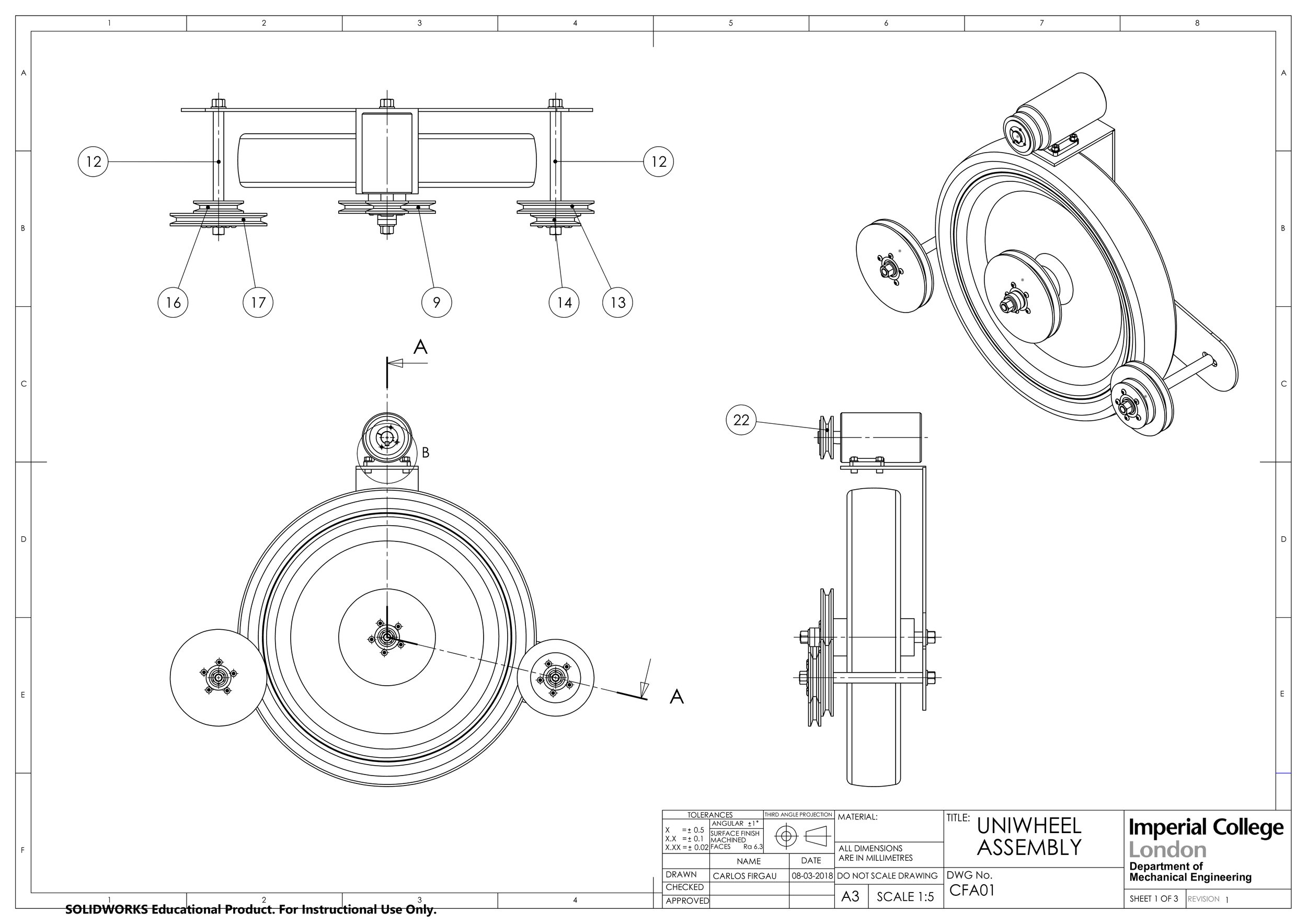

This project consists on the design of a mechanical transmission for a Uni-wheel: a self-balancing single-wheeled vehicle that a person can ride for their daily commute.

Vehicles like these already exist on the market which is why the focus for this project was not to produce a viable competitor for these devices. Instead, the main objective for this project was to get us familiar with correct design practices, to improve our Computer Aided Design skills and to learn to follow appropriate British Standard engineering drawing guidelines.

To develop these skills, this project only focused on the design of the mechanical transmission components. All other subsystems, such as the outer casing of the vehicle as well as the controls, were outside the scope of this project.

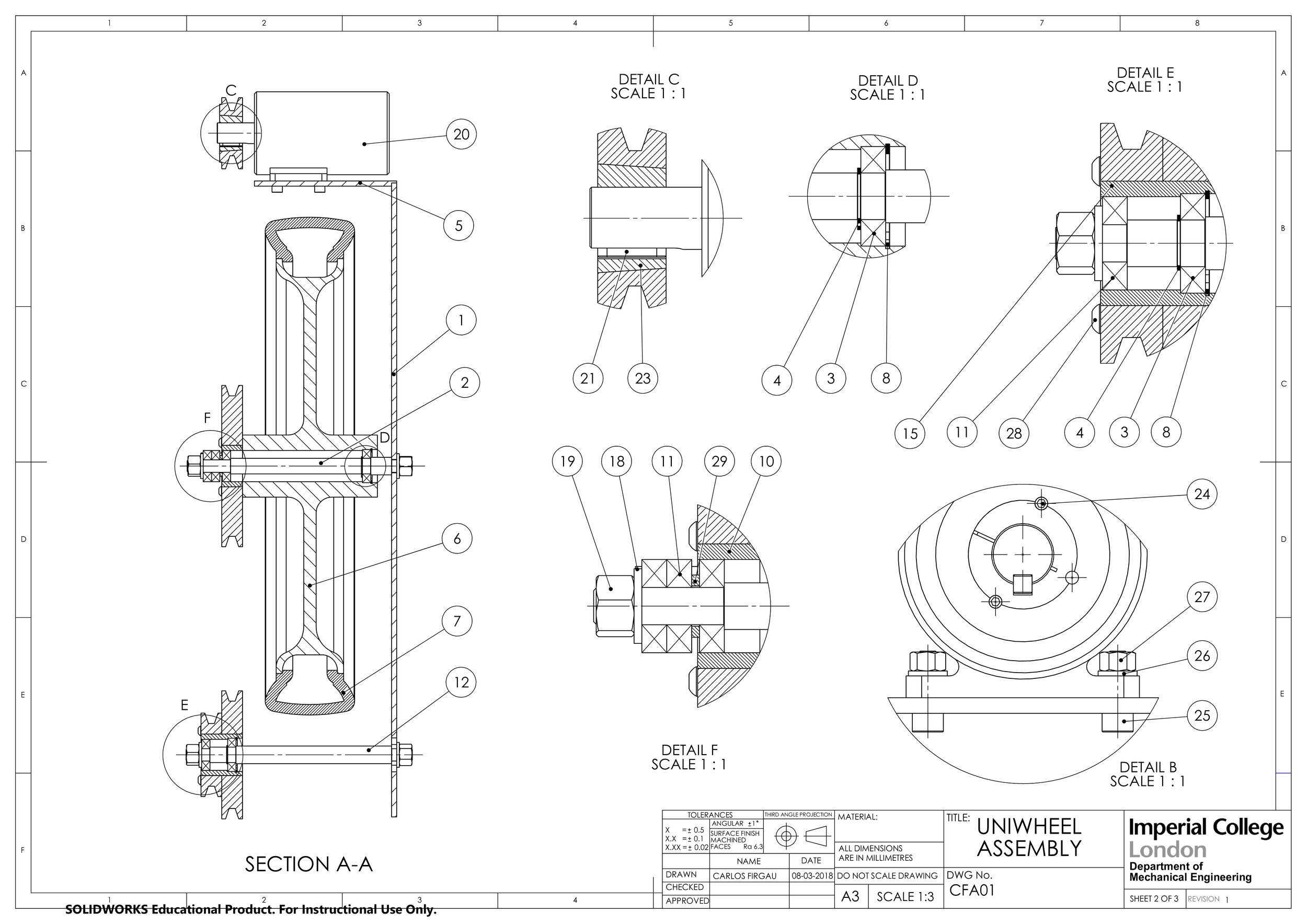

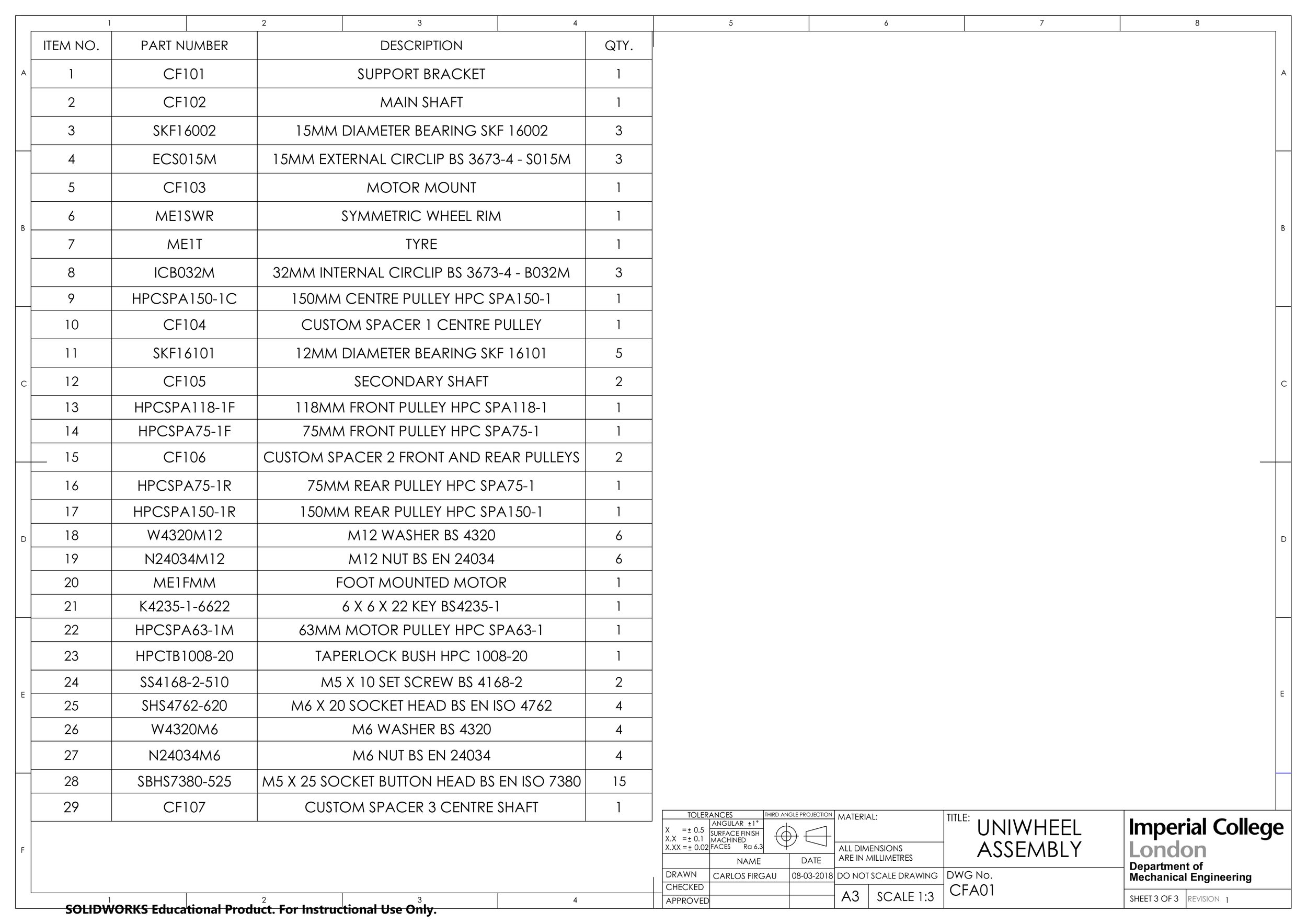

I decided to use a 'Vee' belt and pulley system which would be lighter, quieter, smoother and more convenient to adjust to the correct tension than the alternatives, which included a chain and sprocket system or a gear system. The tensioning of the belt could be achieved by sliding the front and rear secondary shafts outwards and securing in place by tightening the nuts. The supplier selected for the pulley was HPC which limited the possible combinations that could be included in my design - a very common limitation often found in real-world projects. Six pulleys were used in total, mounted onto their shafts using bearings and taperlock bushings, in order to achieve a transmission ratio of 7.5:1.

The results of this project were a CAD model, shown in the pictures below, as well as an assembly drawing and fully-toleranced detailed drawing of the main shaft, both of which I have attached at the bottom of the page.